Electrical maintenance is one of the key components in ensuring the safety and efficiency of any facility’s operations. Facility managers are constantly tasked with balancing proactive maintenance strategies while staying within operational budgets. Thermal imaging services provide a reliable, advanced solution to detect and prevent electrical issues before they escalate.

This post explores the most compelling reasons for incorporating thermal imaging into your electrical maintenance plans. You’ll discover how it contributes to safety, efficiency, cost savings, and long-term reliability.

Enhance Safety Measures

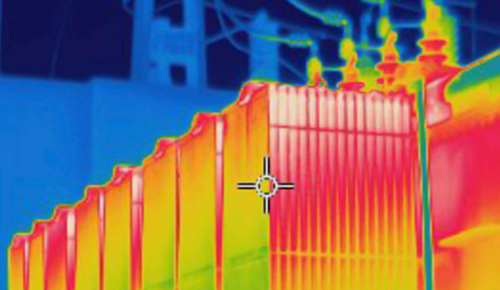

Ensuring safety in a facility is non-negotiable, and electrical malfunctions are one of the leading causes of workplace fires and equipment failures. Thermal imaging offers detailed, non-invasive scans of electrical equipment to help identify abnormalities without the need to disassemble systems.

By identifying overheating components, loose connections, and potential faults early on, thermal imaging helps prevent hazardous situations such as fires or electrical breakdowns. This reduces the risk for employees, occupants, and critical machinery. Maintaining a safer environment not only protects lives but also strengthens an organization’s reputation and compliance with safety regulations.

Prevent Costly Downtime

Downtime caused by unexpected electrical failures can result in significant financial implications for any facility. Thermal imaging inspections are a proactive way to identify weak points or potential issues in electrical systems before they lead to failure.

Many electrical problems, such as overloaded circuits or deteriorating connections, show early signs of excessive heat. Thermal imaging scans can detect these anomalies, giving facility managers the insights needed to address them promptly. This prevents unplanned outages, safeguarding operational continuity.

Additionally, scheduling repairs based on detailed thermal imaging reports allows for maintenance tasks to be coordinated during non-peak hours, minimizing disruptions to productivity.

Reduce Maintenance Costs

A proactive approach to electrical maintenance using thermal imaging can significantly lower overall operational costs. By detecting issues early, you avoid expensive emergency repairs or replacements. Target-specific repairs based on thermal imaging reports eliminate unnecessary maintenance, ensuring cost-effective solutions.

Furthermore, reducing failure rates extends the lifespan of your electrical equipment, further driving down costs over time. Thermal imaging services provide clear, actionable data that empowers facility managers to prioritize investments and allocate budgets wisely.

Improve System Efficiency

Inefficient electrical systems drain energy and increase operational expenses. Thermal imaging plays a vital role in identifying components that are damaged, worn, or operating inefficiently. Examples include overloaded circuits, unbalanced loads, or poorly maintained connections.

These inefficiencies often result in excessive energy consumption and performance bottlenecks. By addressing these issues, facilities can optimize their electrical systems for better energy efficiency and reliability.

Enhanced efficiency doesn’t just save money—it also reduces a facility’s carbon footprint, a critical step in meeting sustainability goals and complying with environmental regulations.

Meet Compliance Standards

Many industries are subject to strict regulations and safety compliance standards. Failing to adhere to these standards can lead to costly penalties, legal actions, and damage to business reputation. Thermal imaging services help ensure compliance by maintaining the integrity of electrical systems.

Through professional thermal imaging inspections, operators can generate detailed reports and documentation proving adherence to safety guidelines and industry standards. These records not only support audits but also provide peace of mind about the ongoing reliability of electrical systems.

Final Thoughts

Thermal imaging services are a valuable tool for addressing the complexities of electrical maintenance. From enhancing safety to improving efficiency and reducing costs, these inspections deliver tangible benefits across all aspects of facility management.

A proactive maintenance approach using thermal imaging will help mitigate risks, protect assets, and support smooth, uninterrupted operations—all while demonstrating a commitment to innovation and best practices in your industry.

If you’re ready to optimize your facility’s electrical systems with professional diagnostics, explore thermal imaging services from trusted companies like Reinhold Electric today. Make better decisions, reduce risks, and ensure the longevity of your operations.